Wristband Machine

Wristband Machine Specification

- Weight

- 190 kg

- Function

- Automatic Knitting of Wristbands

- Color

- Blue and White

- Lead Time

- 20 Days

- System Support

- Single System

- Speed

- 800 RPM

- Racking

- Single Racking

- Dimension (L*W*H)

- 70 x 52 x 160 cm

- Knitting Method

- Circular Knitting

- Knitted Type

- Flat Knitted

- Product Type

- Wristband Machine

- Power

- 1.5 kW

- Application

- Sports Wristband Manufacturing

- Condition

- New

- Control System

- Advanced Touch Screen

- Drive Type

- Servo Motor Drive

- Gauge

- 12G

- Needle

- Electronic Needle Selection

- Stitch Density

- Adjustable

Wristband Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 1-4 Months

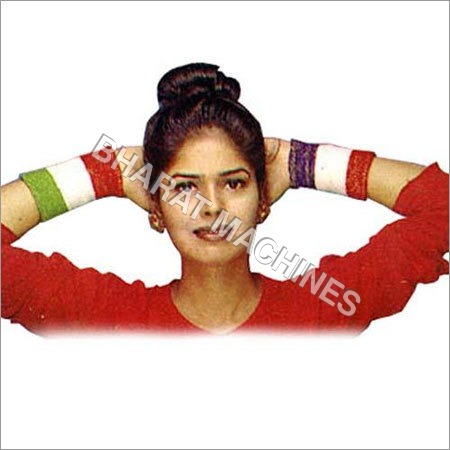

About Wristband Machine

We have marked a distinct position in the domain by providing fine quality Wristband Machine that is utilized for designing wrist bands. This machine is designed and manufactured using supreme grade components and advanced technology in adherence with predefined international industry norms under the direction of experts. Available in several technical specifications to fulfill the different application requirements of our clients, this Wristband Machine can be availed from us at an economical price range.

Features:

- Rugged design

- Impeccable performance

- Negligible maintenance

- Longer service life

Efficient Automation for Wristband Manufacturing

Engineered for efficiency, the wristband machine features automatic circular knitting paired with a single racking system, streamlining the entire manufacturing process. Its advanced touch screen interface simplifies operation, letting you adjust stitch density and patterns as production demands change. The system is optimal for the rapid creation of flat-knitted sports wristbands, reducing labor while guaranteeing consistent output.

Precision and Quality with Advanced Technology

Equipped with electronic needle selection and a servo motor drive, this machine produces uniform and high-quality wristbands at impressive speeds of up to 800 RPM. Adjustable gauge (12G) ensures versatility for a range of wristband specifications. The sturdy build (dimensions: 70 x 52 x 160 cm) ensures reliable, long-term performance for manufacturers and exporters focused on product excellence.

FAQs of Wristband Machine:

Q: How does the wristband machines automatic knitting function work?

A: The machine utilizes a circular knitting method combined with electronic needle selection and a single racking system to automatically create flat-knitted sports wristbands. The control system allows operators to set parameters via the advanced touch screen, enabling seamless, hands-free production.Q: What is the process for adjusting stitch density on the machine?

A: Stitch density can be easily adjusted through the touch screen interface. Operators can configure the settings before or during operation to suit different wristband designs, ensuring customizable product output without halting production.Q: When is the ideal time to use this machine in wristband production?

A: This machine is best suited for the main production phase of sports wristbands, particularly when high efficiency and consistency are required. Its automated operation allows for large-scale manufacturing without manual intervention.Q: Where can this wristband machine be utilized?

A: It is ideal for factories, sportswear manufacturing facilities, and textile production units in India or similar markets, especially for manufacturers, exporters, distributors, and suppliers seeking to enhance wristband production capability.Q: What benefits does the advanced touch screen control system provide?

A: The touch screen streamlines machine operation, granting quick adjustments such as stitch density or speed. It offers user-friendly controls, allowing even less experienced operators to manage production efficiently.Q: How does the servo motor drive contribute to machine performance?

A: The servo motor drive ensures precise, efficient, and reliable movement within the machine, supporting steady speeds of up to 800 RPM. This enhances productivity and contributes to the overall quality and consistency of the wristbands produced.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wrist Band & Sweat Bands Knitting Machine Category

Sweat Bands Knitting Machine

Minimum Order Quantity : 1 Piece

Product Type : Textile Knitting Machine

Drive Type : Electric

Condition : New

Warranty : 1 Year

Application : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS